Power transformer temperature field monitoring and flame detection system

- Categories:Solution

- Author:

- Origin:

- Time of issue:2020-08-05

- Views:0

(Summary description)The first part is to use infrared dual light camera to monitor the temperature field and analyze the temperature data of the power transformer in operation for 24 hours. The data mining technology is used to provide guidance for the operation of the transformer.

Power transformer temperature field monitoring and flame detection system

(Summary description)The first part is to use infrared dual light camera to monitor the temperature field and analyze the temperature data of the power transformer in operation for 24 hours. The data mining technology is used to provide guidance for the operation of the transformer.

- Categories:Solution

- Author:

- Origin:

- Time of issue:2020-08-05

- Views:0

Program overview:

Power transformer temperature field monitoring and flame detection system is mainly divided into two parts.

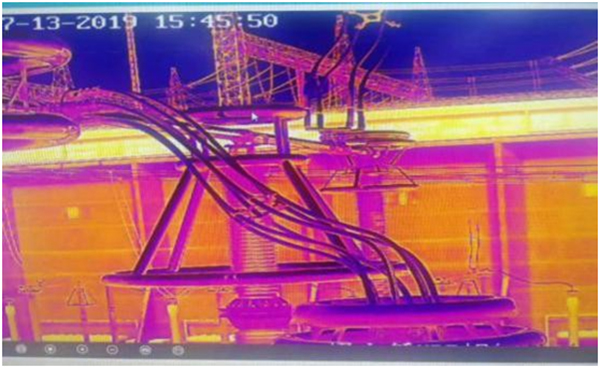

The first part is to use infrared dual light camera to monitor the temperature field and analyze the temperature data of the power transformer in operation. The data mining technology is used to provide guidance for the operation of the transformer, and early warning is given for the abnormal temperature or exceeding the threshold value.

The second part is the flame detection part. Before the fire, some equipment will have some abnormal working state and operating temperature. According to the first part, the inspector can give early warning in advance. However, when the fire is very sudden, the camera can directly capture the flame signal and link with the local fire fighting and local fire-fighting facilities to timely cut off the power supply of the transformer equipment The fire location is used to judge the burning materials, and the corresponding fire extinguishing agent is used for scientific and effective fire extinguishing treatment. Moreover, the system has the function of data storage and intelligent analysis, which can record and analyze the data of power transformer failure, and provide big data fault prediction function for customers.

Background and advantages:

Large power transformer is the main step-down transformer used for power transmission and transformation in the substation. It is the core part of the substation. Its capacity is large and the working environment is relatively bad. There are some hidden dangers in the inspection of operation and maintenance personnel. Once the fault or fire occurs, it will cause great loss of personnel and property, which does not reach the normal operation of the regional transmission system. At present, the main faults of power transformer are: the main transformer oil temperature rise caused by radiator blockage, insulation aging of solid insulation materials, etc., which are accompanied by abnormal temperature. Therefore, in order to take effective protective measures, monitoring the temperature of power transformer is an effective means. Analyzing its temperature data can infer the operation of the transformer, and for abnormal phenomena, it can be used for operation Maintenance personnel provide corresponding decision-making services.

- The technical products are reliable and stable

- Good human-computer interaction interface is easy to read and operate

- Intelligent analysis algorithm of implanted temperature data

- The temperature measurement range is wide, and the accuracy can reach ± 2 ℃

- The detection range is wide, which can meet the needs of monitoring multiple transformers at the same time

- The system has alarm data interface, which can be connected to the government enterprise platform

Solution:

The system is mainly composed of front-end infrared dual light camera, temperature and flame detection software. The 24-hour infrared temperature field detection is carried out for the equipment detected by the camera. In case of any abnormality, the maintenance level is recommended according to the measured temperature value on site. If the temperature jump is large, it will prompt the power failure for maintenance; when the fire occurs, the fire will be automatically reported, and the on-site disposal progress can be displayed in real time through 3D panorama and live video, so as to guide the safety and order of the site To carry out fire emergency disposal; to realize the monitoring and perception of fire hazards in converter station.

1) Data acquisition and parameter setting

Real time acquisition of temperature data and image data from the infrared thermal imaging device in the monitoring field of view, including the setting of infrared camera parameters.

2) Temperature field monitoring and analysis module: real time analysis of temperature information in the monitoring area, monitoring whether there is temperature change or continuous increase phenomenon, and provide early warning signal.

3) Data analysis: in the flame detection, the dynamic, contour and temperature information of the flame should be combined to identify, according to the three joint discrimination to reduce false alarm, the system adopts the random forest method, the sample number reaches 10000 levels; the algorithm adopts the characteristic method based on the flame contour, and uses the temperature information to filter out the flame background information.

4) Image display: refresh and display the thermal image distribution information within the monitoring field of view, and display the position coordinate information (at most 3 places) on the image in case of fire.

5) Alarm module: if it is judged that there is flame in the monitoring field of view, it will send out an alarm signal.

6) Data storage: it can store the alarm automatically from the time when the alarm event is detected to the time when the alarm is effectively stopped and removed

(scene map)

Scan the QR code to read on your phone

Keep in contact

E-mail:mail.syseic.com

Copyright Shenyang Tianyan Zhiyun Information Technology Co., Ltd